Lake Isabella Dam

For our customer Flatiron/ Dragados, we built galvanized steel stairs and railings on this unique army corps of engineers project in Lake Isabella CA. We learned much about anchoring into granite rock for one of

Home » Projects

For our customer Flatiron/ Dragados, we built galvanized steel stairs and railings on this unique army corps of engineers project in Lake Isabella CA. We learned much about anchoring into granite rock for one of

Cody Builders Supply provided 2.9 million dollars of misc. metals for the Sacramento Regional WWTP (Echowater) project. The scope included all the metals in Spec section 5 to include: stainless steel built-up tube baffles, grating,

Liner and cover replacement in Granite Bay, CA. We created a sloping stainless steel rack to support the new cover over this reservoir for the San Juan Water District. There were multiple compound sloping surface

East River Greenway Sea Rails in Manhattan, NY. We provided nearly one mile of picket fence for this new park/ jogging path built into the East river. Read more: EDC.NYChttps://edc.nyc/project/east-midtown-waterfront New York Yimbyhttps://newyorkyimby.com/2023/03/east-midtown-greenway-nears-completion-along-the-sutton-place-waterfront-in-midtown-manhattan.html

Oceanic Companies, Inc. was the mechanical subcontractor on this project. We fabricated pipe supports, straps etc. It was a challenging project both in schedule and detailing / fabricating. See below the project description from the

Cody Builders Supply fabricated roof railings and miscellaneous metals for the new LaGuardia Airport Pedestrian Bridge B in 2020 (Southwest terminal). The Brooklyn Diner stainless steel cladding was a unique piece of work within Pedestrian

Cody Builders Supply fabricated the steel bracing, walers and rakers to support the excavation at the Hudson Square site in New York for the new Walt Disney Company headquarters. The schedule was very challenging and

Cody Builders Supply fabricated curved aluminum launders, baffles, and weirs for the Piscataway Secondary Clarifiers WSSC project. These wrap around five clarifier tanks to allow the clean water to be separated from the dirty water.

On this design build project, special care and attention had to be taken to the welding sequencing and control of heat distortion due to the thousands of welds required on the enclosures. Cody also devised

Cody provided complete supply of all structural, miscellaneous and ornamental metals for this project. Deliveries had to be staged with active traffic below the station and coordinated tightly with the erector. Cody overcame challenges in

Cody supplied over 150 Truckloads of fabricated steel permanent struts and wales for support of excavation for the Union Square Market Street subway station in San Fransisco, CA. We also provided the complete structural steel

Cody assisted with the design of the key components of the station by providing mock ups and renderings to the design team in advance of completed design information so as to keep up with the

The biggest challenge was buying all the steel material for the RO Building in 2021 when the price of steel was rising dramatically. We bought a lay down yard to bring material in and store

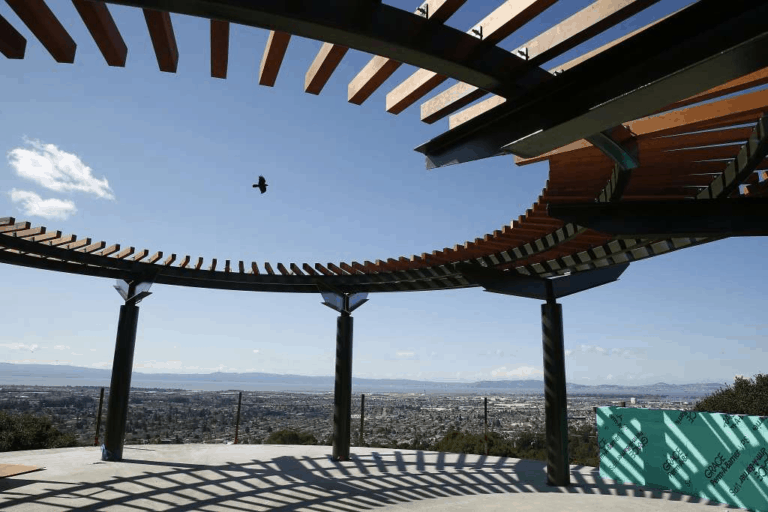

The bison viewing area of the new California Trail exhibit at the Oakland Zoo. Slated to open in 2018. Cody Builders fabricated the circular canopy with the eagle flying above it.

Complete miscellaneous metals and structural steel for finishes. Complete Service Carrier system for mezzanine and platform levels, full metals supply for project with entrances and ancillary buildings Click to enlarge

Year Completed: 2015 | Owner: Sacramento Regional Transit District | General Contractor: Balfour Beatty Infrastructure, Inc. | Sub Contract Value: $1,070,000 Subcontract Scope / Description of Work: Steel framing, handrails and complex architecturally exposed station canopies

© 2024 Cody Builders Supply. All Rights Reserved.